Marike Andeweg

Name

Marike Andeweg

Name

Marike Andeweg

Name

Marike Andeweg

Location

Rotterdam

Location

Rotterdam

Location

Rotterdam

Year

2024

Year

2024

Year

2024

Client

Marike Andeweg

Client

Marike Andeweg

Client

Marike Andeweg

Utilization

Design

Utilization

Design

Utilization

Design

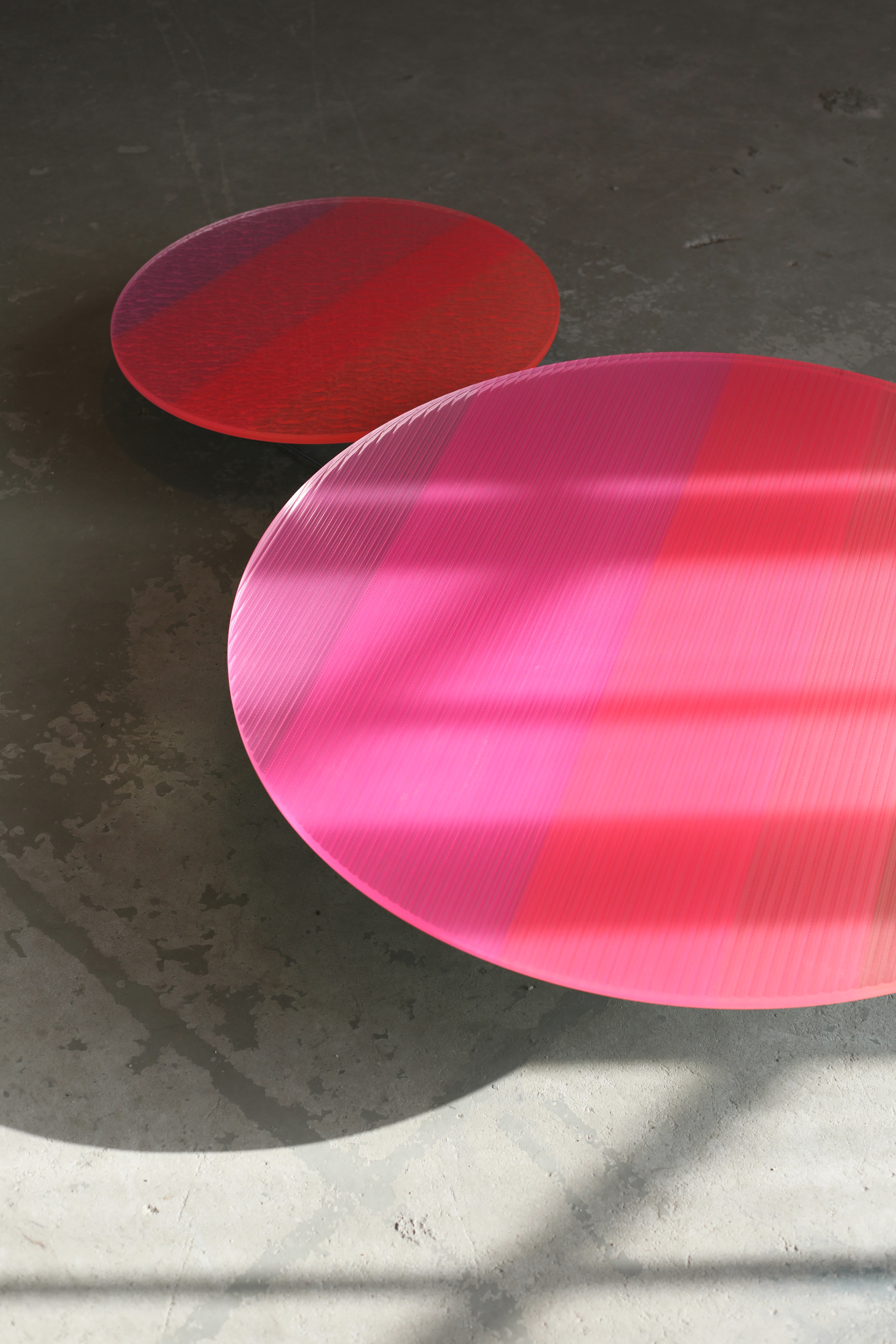

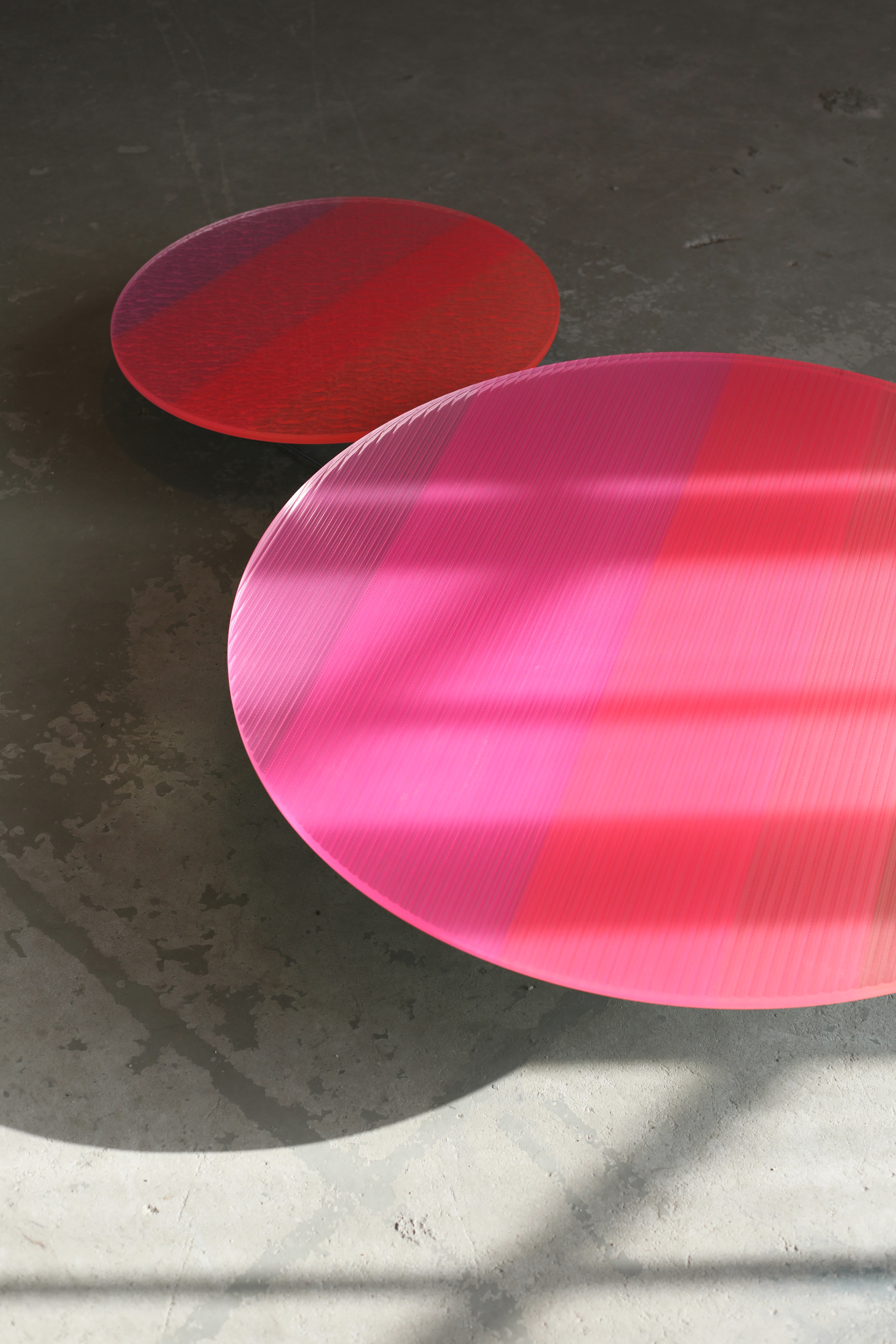

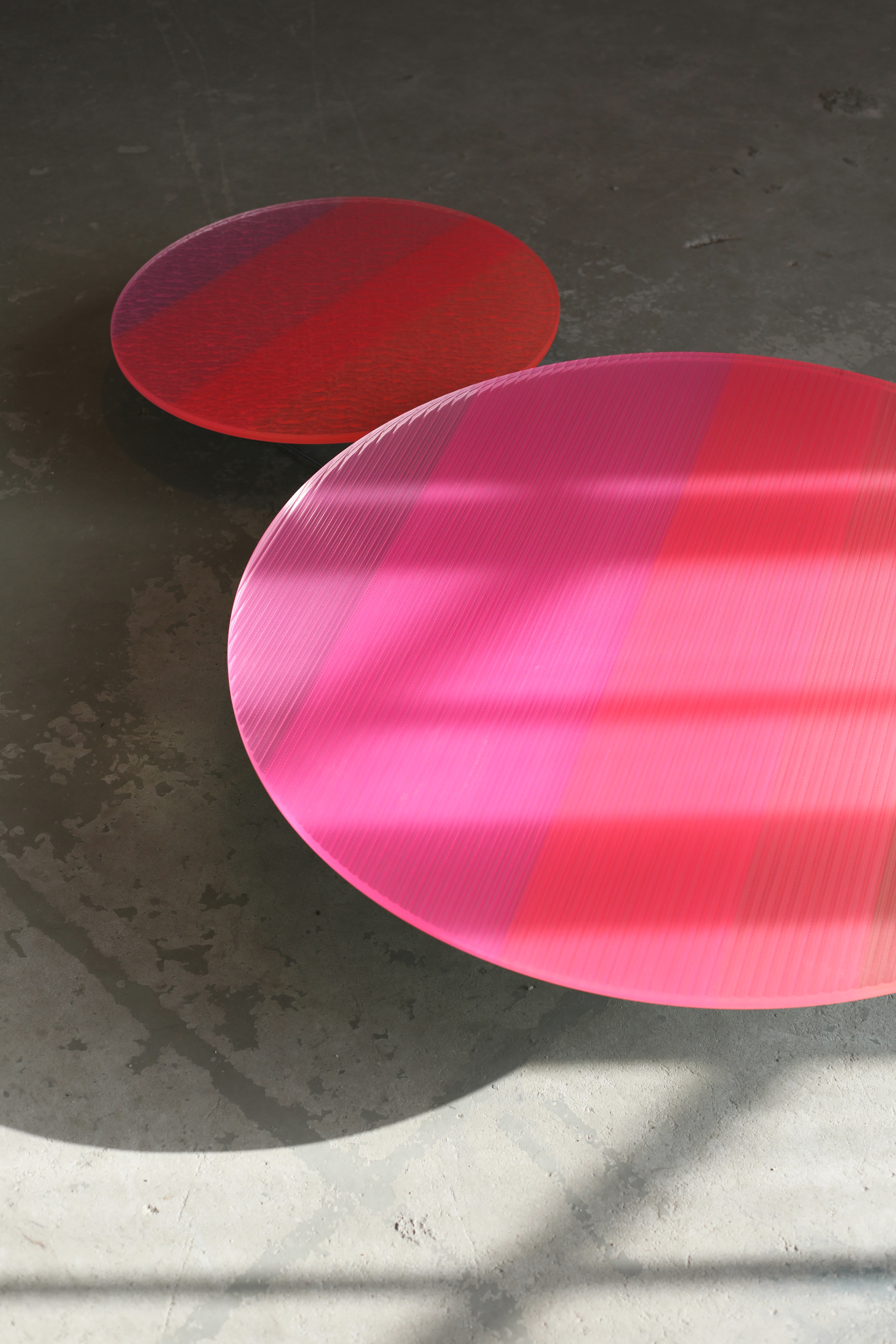

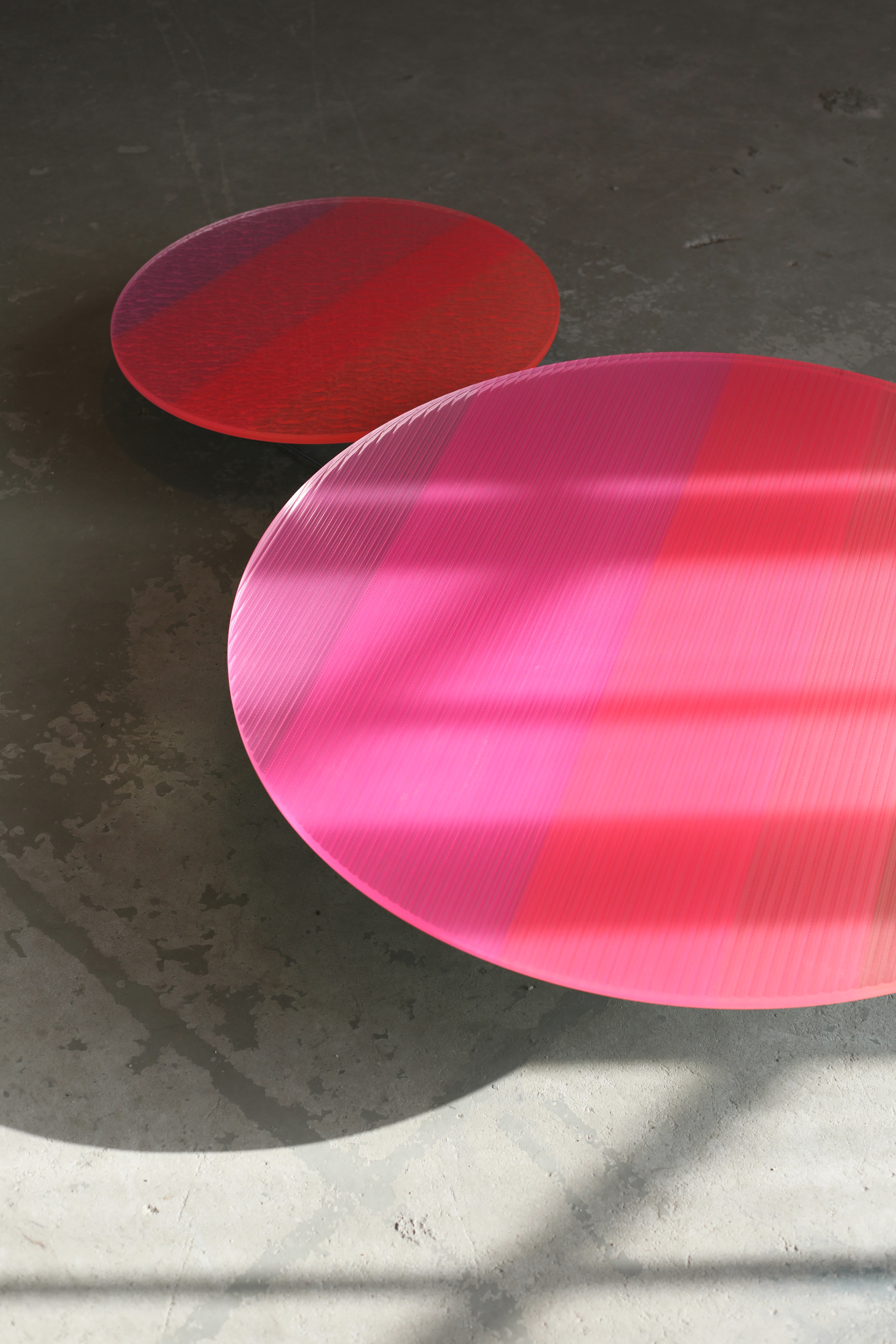

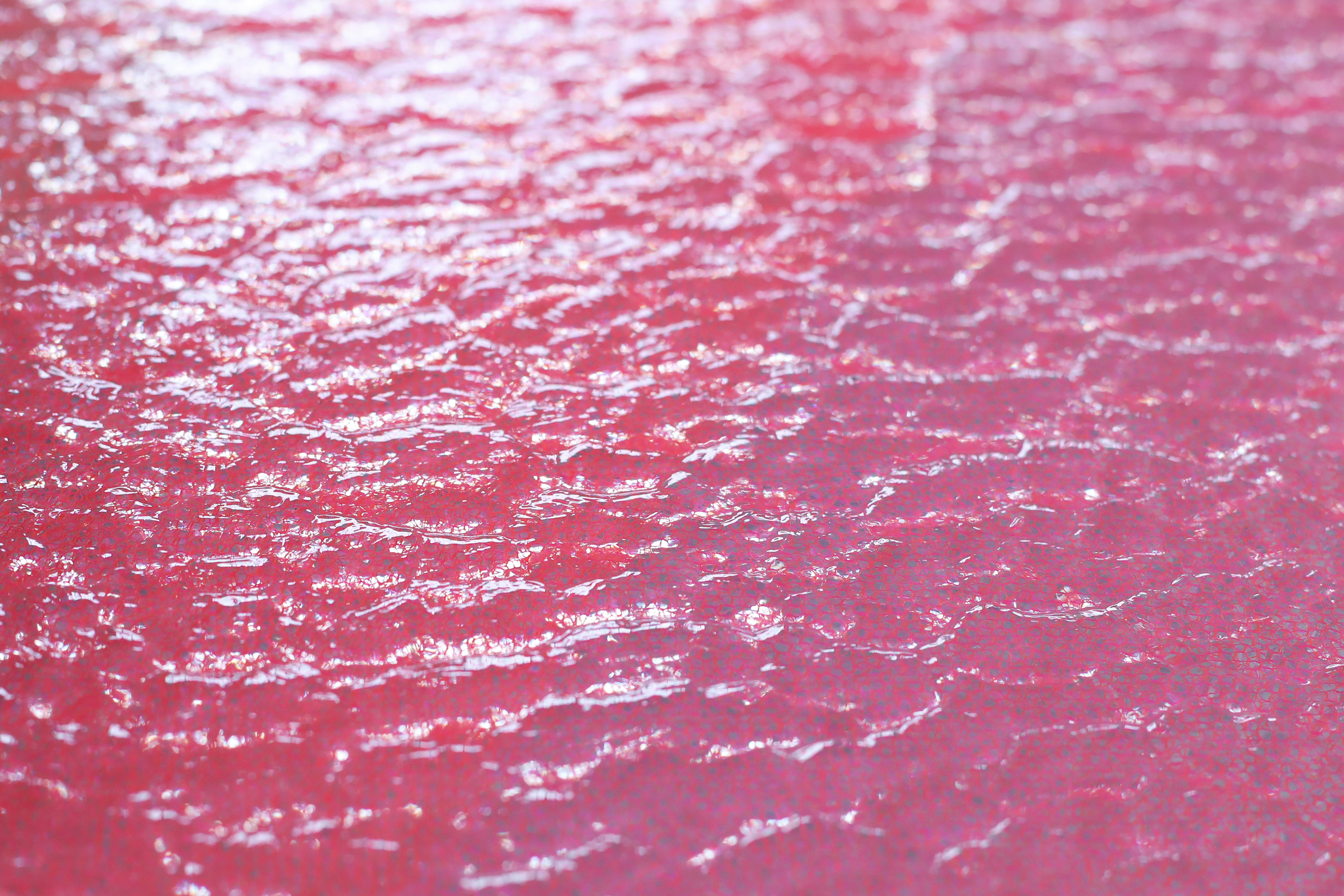

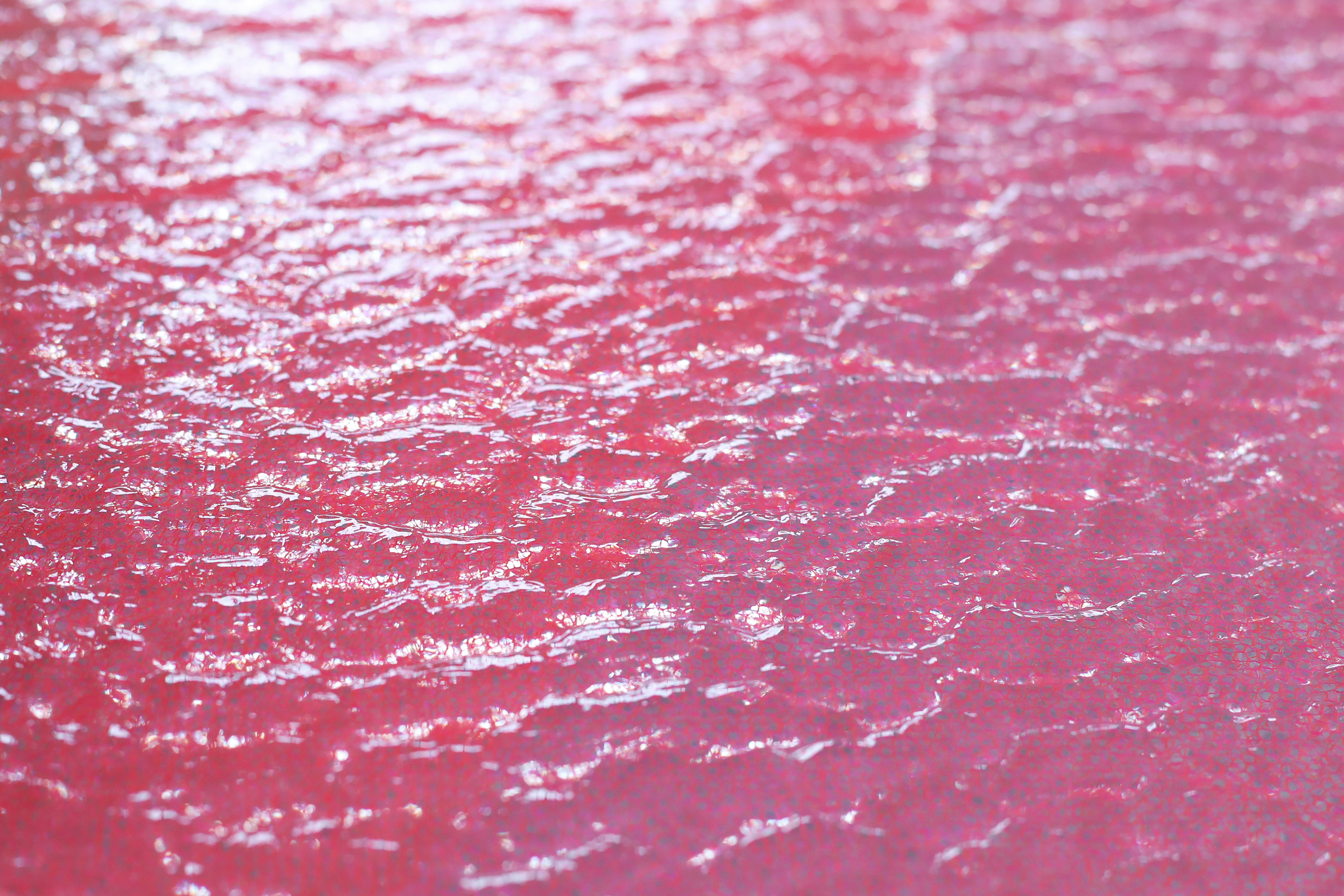

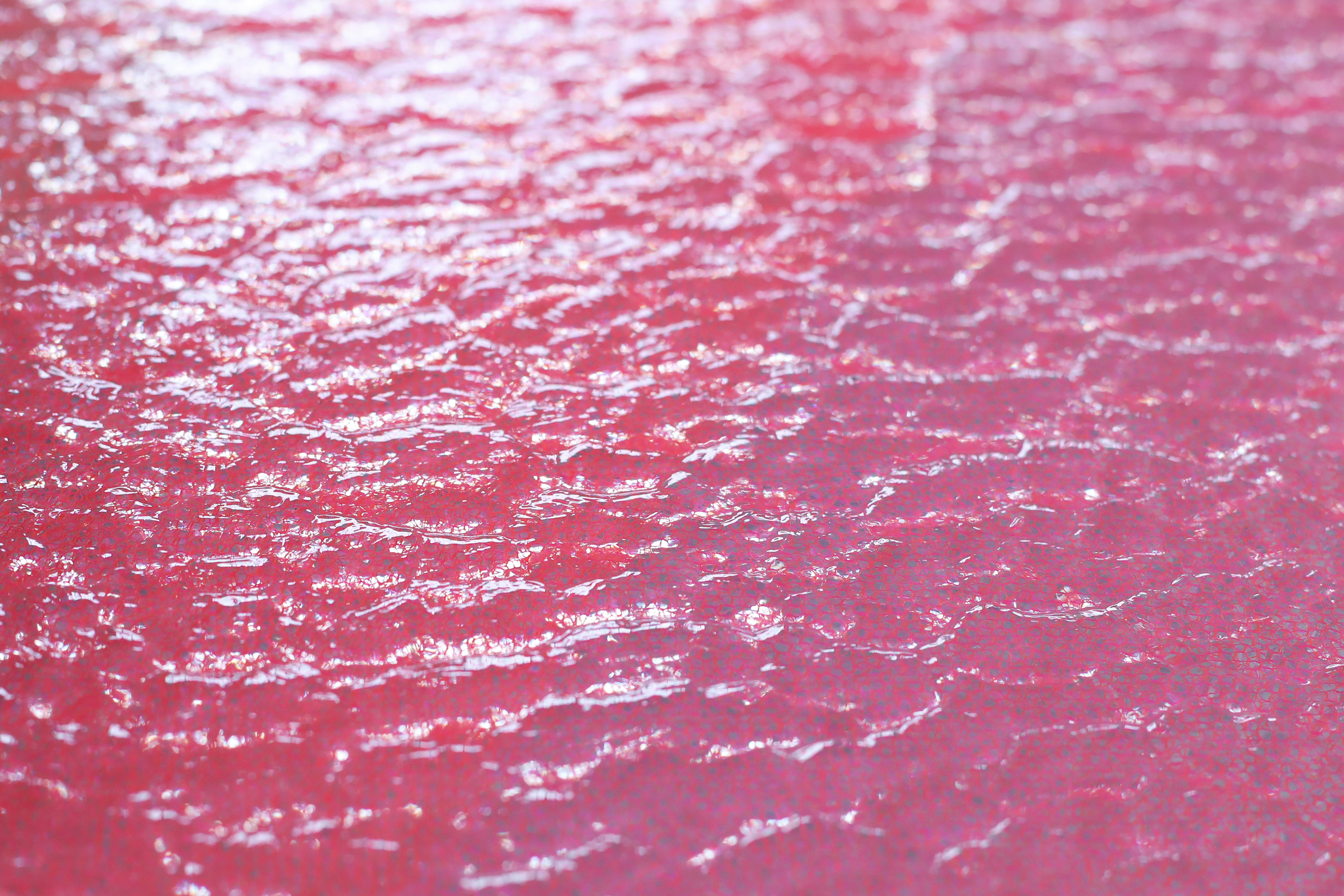

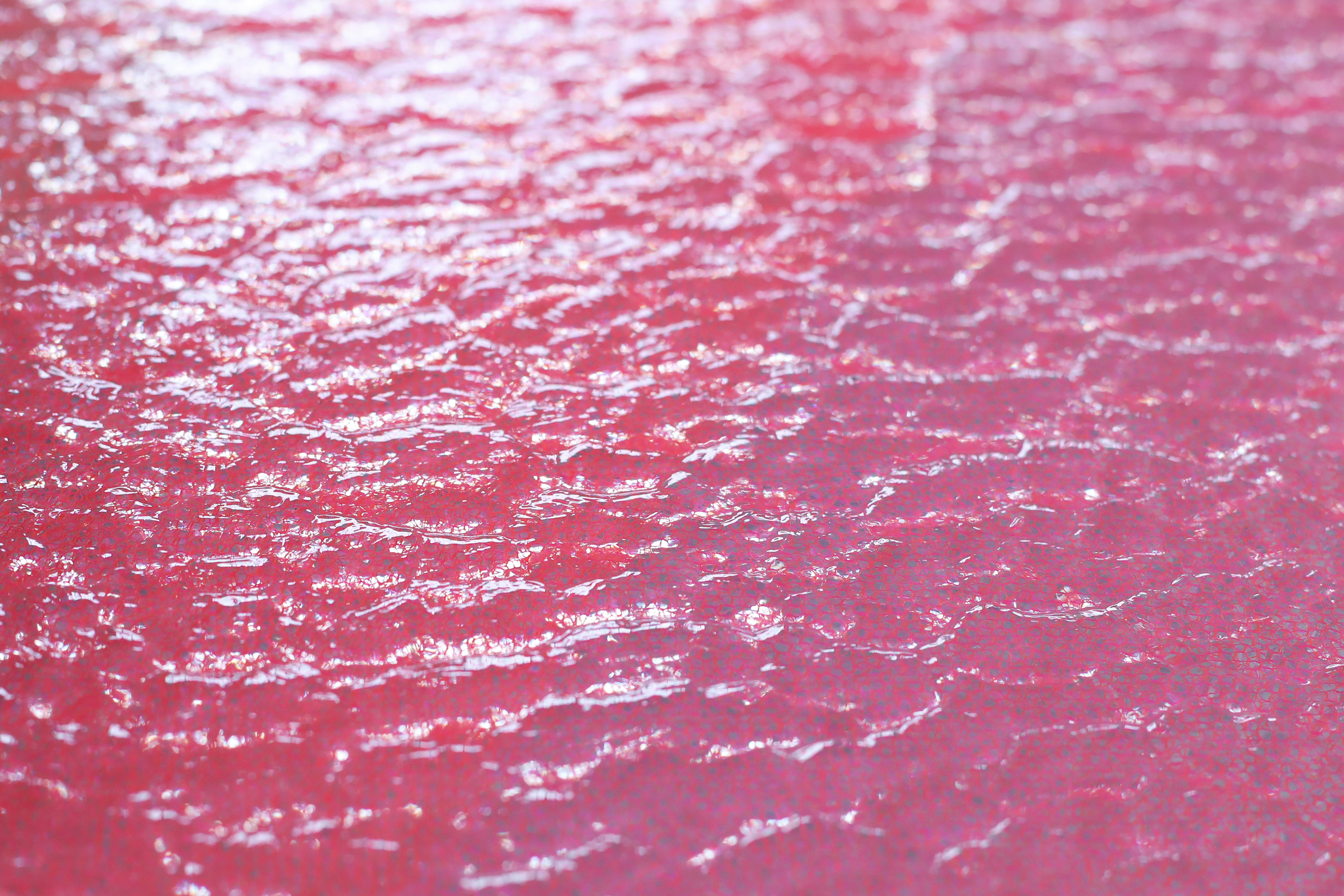

Marike Andeweg's collection, revealed at Object Rotterdam, marks a notable contribution to the design world, skillfully blending wall art and floor objects. Each piece showcases a marriage of innovative print techniques with special lamination, pushing the boundaries of traditional design. This approach results in visually striking, expressive pieces that demand attention and interaction. The use of advanced lamination not only enhances visual depth but also adds a tactile quality, making each item a unique exploration of texture and form.

Marike Andeweg's collection, revealed at Object Rotterdam, marks a notable contribution to the design world, skillfully blending wall art and floor objects. Each piece showcases a marriage of innovative print techniques with special lamination, pushing the boundaries of traditional design. This approach results in visually striking, expressive pieces that demand attention and interaction. The use of advanced lamination not only enhances visual depth but also adds a tactile quality, making each item a unique exploration of texture and form.

Marike Andeweg's collection, revealed at Object Rotterdam, marks a notable contribution to the design world, skillfully blending wall art and floor objects. Each piece showcases a marriage of innovative print techniques with special lamination, pushing the boundaries of traditional design. This approach results in visually striking, expressive pieces that demand attention and interaction. The use of advanced lamination not only enhances visual depth but also adds a tactile quality, making each item a unique exploration of texture and form.

Techniques

Techniques

Techniques

Special Lamination

Our special lamination service includes embedding mesh within glass layers, enhancing both aesthetics and durability. Open to using a variety of materials, we welcome challenges to innovate beyond conventional lamination. This approach enables custom, creative solutions for unique design and structural needs.

Special Lamination

Our special lamination service includes embedding mesh within glass layers, enhancing both aesthetics and durability. Open to using a variety of materials, we welcome challenges to innovate beyond conventional lamination. This approach enables custom, creative solutions for unique design and structural needs.

Color Lam

The technology offers unmatched transparency, vibrant colors, and a crystal-clear appearance, setting an industry standard. Its wide color spectrum, high-resolution printing, and lamination options with various glass types enable limitless design possibilities.

Color Lam

The technology offers unmatched transparency, vibrant colors, and a crystal-clear appearance, setting an industry standard. Its wide color spectrum, high-resolution printing, and lamination options with various glass types enable limitless design possibilities.

Polishing

After cutting the glass, sharp edges are removed through grinding and polishing. This process, known as "Poli," includes coarse pre-grinding, fine re-grinding, and finally polishing.

The maximum thickness that can be processed is 55 mm, with which we strive to achieve a high-quality finish that is not only functional, but also aesthetically pleasing to the highest standards.

Polishing

After cutting the glass, sharp edges are removed through grinding and polishing. This process, known as "Poli," includes coarse pre-grinding, fine re-grinding, and finally polishing.

The maximum thickness that can be processed is 55 mm, with which we strive to achieve a high-quality finish that is not only functional, but also aesthetically pleasing to the highest standards.

Polishing

After cutting the glass, sharp edges are removed through grinding and polishing. This process, known as "Poli," includes coarse pre-grinding, fine re-grinding, and finally polishing.

The maximum thickness that can be processed is 55 mm, with which we strive to achieve a high-quality finish that is not only functional, but also aesthetically pleasing to the highest standards.